Competitive Performance

Helisem Standard Vertical Mixer Series

Trusted by professionals in water treatment, chemicals, paints, pharmaceuticals, lubricants, agriculture, and more. Helisem mixers are engineered for power, precision and performance.

Why Choose Us?

HELISEM mixers offer up to 70% energy savings compared to previous models, helping you reduce operational costs without compromising performance. Designed for quick, safe, and cost-effective installation, they’re lightweight and easy to handle, minimizing downtime and setup expenses. As one of the most competitive mixer series on the market, HELISEM delivers outstanding value with proven reliability across a wide range of industries.

Built to handle operating volumes from 10 liters to 1,300 m³ and viscosities up to 1,000 cP, these mixers support low, medium, and high agitation needs with ease. Whether you're blending, dissolving, homogenizing, or suspending, HELISEM® provides consistent results for water treatment, chemicals, paints, pharmaceuticals, lubricants, agriculture, and more.

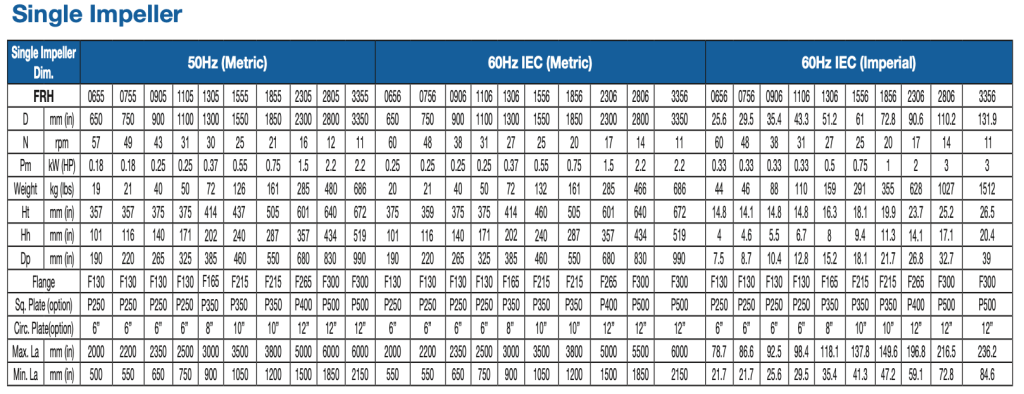

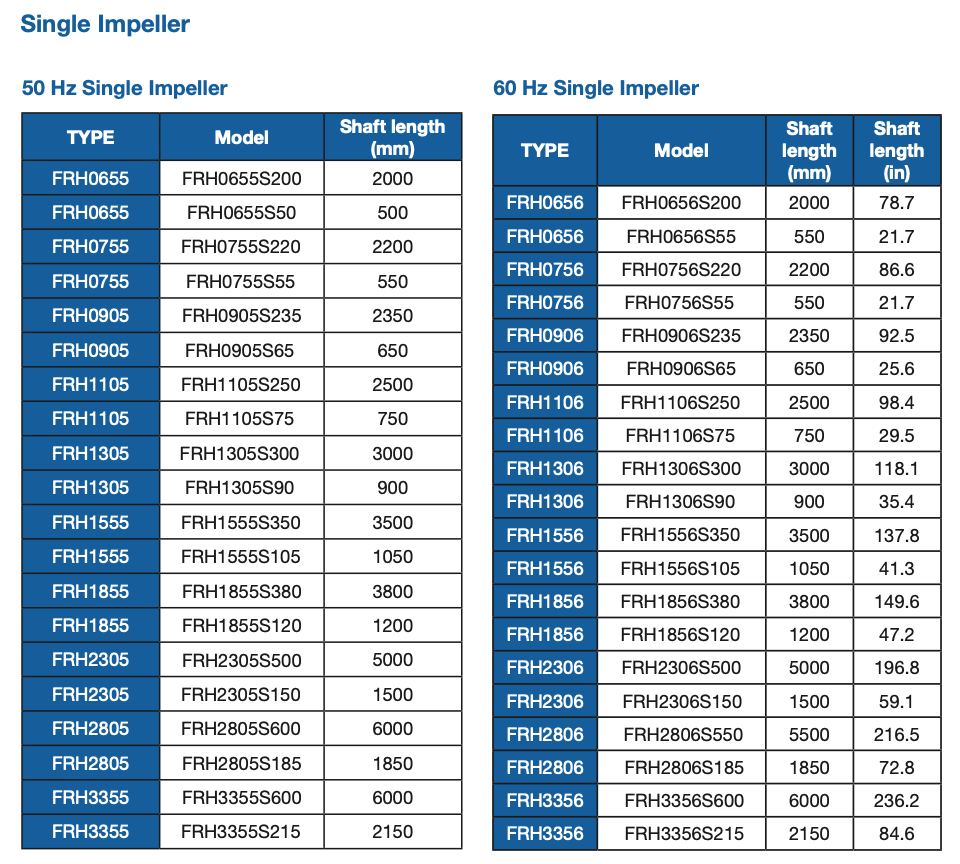

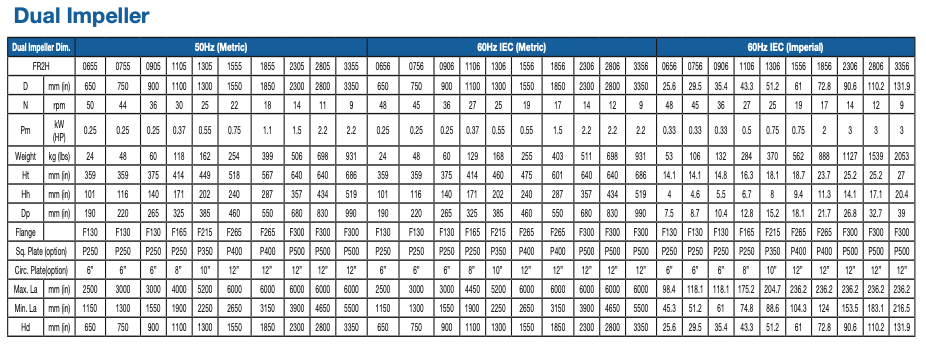

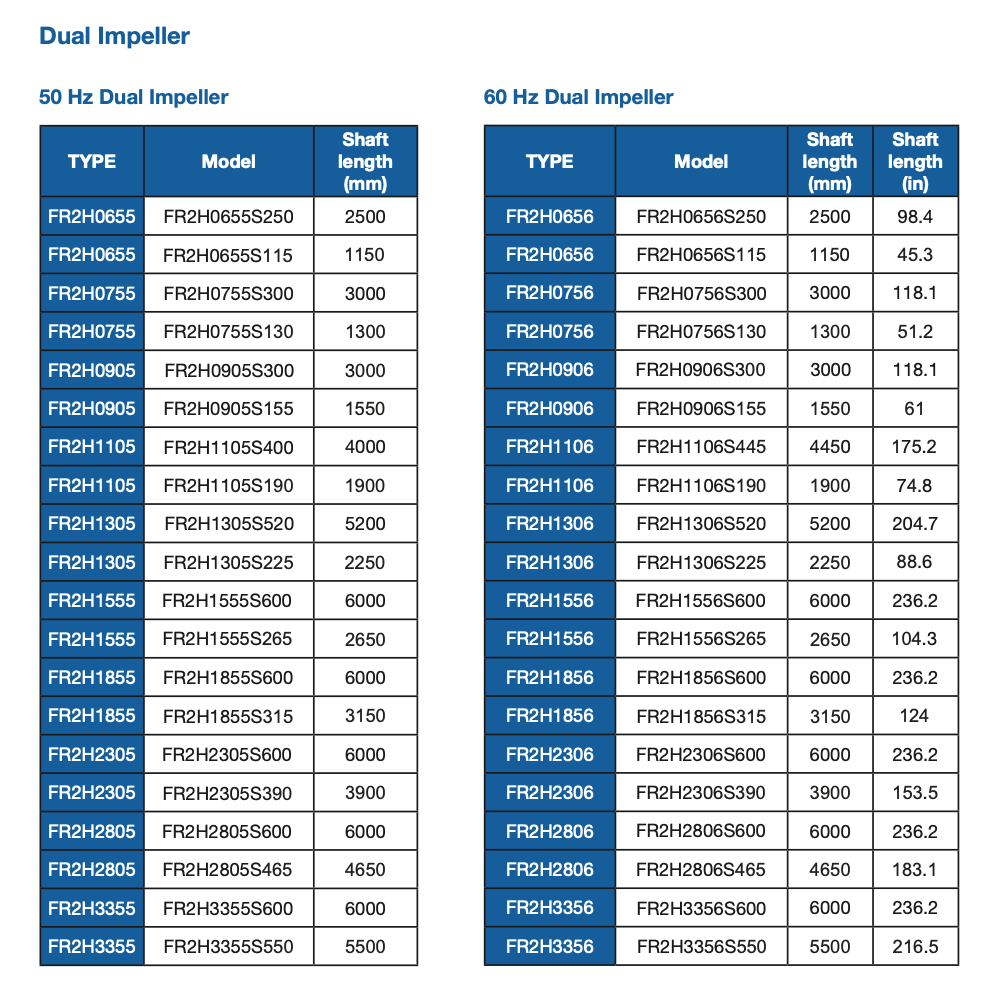

FRH series

Energy-Efficient Mixing,

Built for Flocculation Excellence

With the FRH mounted with a HXP impeller, to support a wide range of open or closed tank applications up to 11m (36ft) diameter (1950m³ – 515000 gallons) and viscosities up to 1000 mPas (cP) at 1.3 specific gravity.

The FRH model is a gearmotor driven mixer equipped with the HXP- HP2 impeller with 2 blades. This model was specifically designed for flocculation in water treatment. The HP2 impeller is designed to generate good flow with the least shear possible, making it ideal for flocculation.

The compact FRH model provides energy efficiency in a lightweight mixer with uncompromising results.

Gear-driven motor for consistent performance

Hydrofoil HXP-HP2 impeller with 2 blades

Energy-efficient and compact design

Designed for flocculation with low shear flow

Easy to install and maintain

Operates during filling and emptying

Compatible with frequency inverters

Available with 1 or 2 impellers

Upward or downward flow options

Optional coating on wetted parts (Abcite)

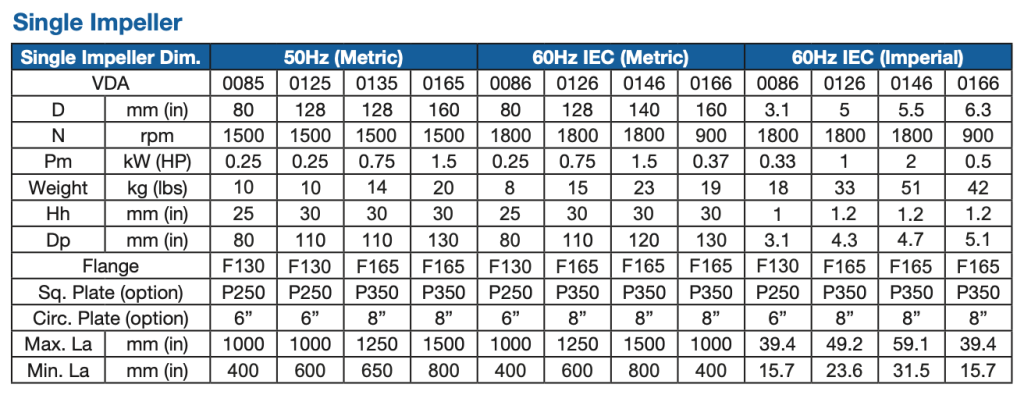

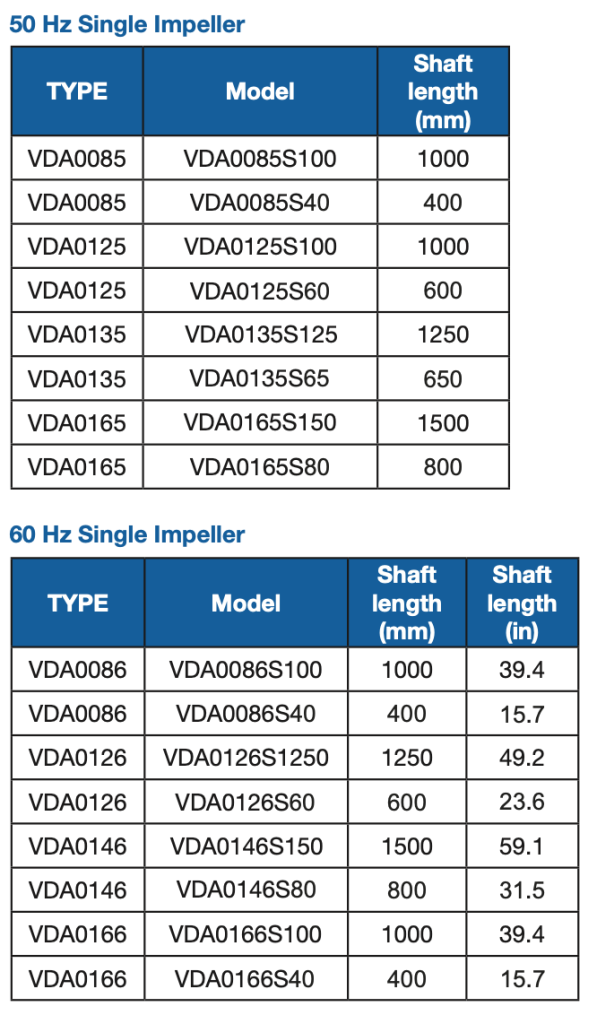

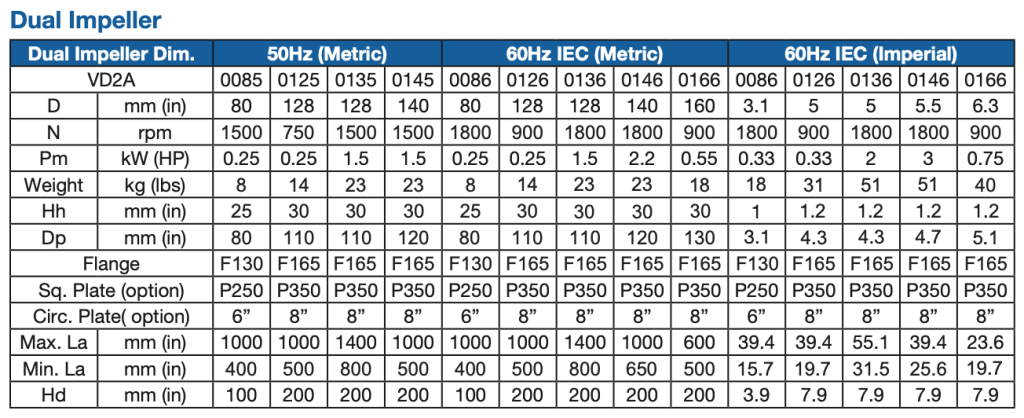

VDA Series

Smart Mixing for Tight Spaces

With the VDA having a specific impeller, to support a wide range of open or closed tank applications up to 1.4m (4.75ft) diameter (4.4 m³ – 1200 gallons) and viscosities up to 1,000 mPas (cP) at 1.3 specific gravity.

The VDA model is a motor driven mixer available with a variety of marine impellers and mounting options.

Powerful and compact, the VDA model provides energy efficiency in a light-weight mixer with uncompromising results.

Motor-driven mixer with compact, energy-efficient design

Compatible with a variety of marine impellers

Ideal for small tank applications with high-performance mixing

Supports both open and closed tank setups

Easy to install and maintain

Available with short lead times for fast deployment

Multiple mounting options to suit different tank types

Stainless steel 316L wetted parts for excellent corrosion resistance

PU-painted drive system (RAL 1018) for durability

Optional ATEX version for hazardous environments

Optional powder coating (Abcite)

Suitable for outside operation

Available with 1 or 2 impellers

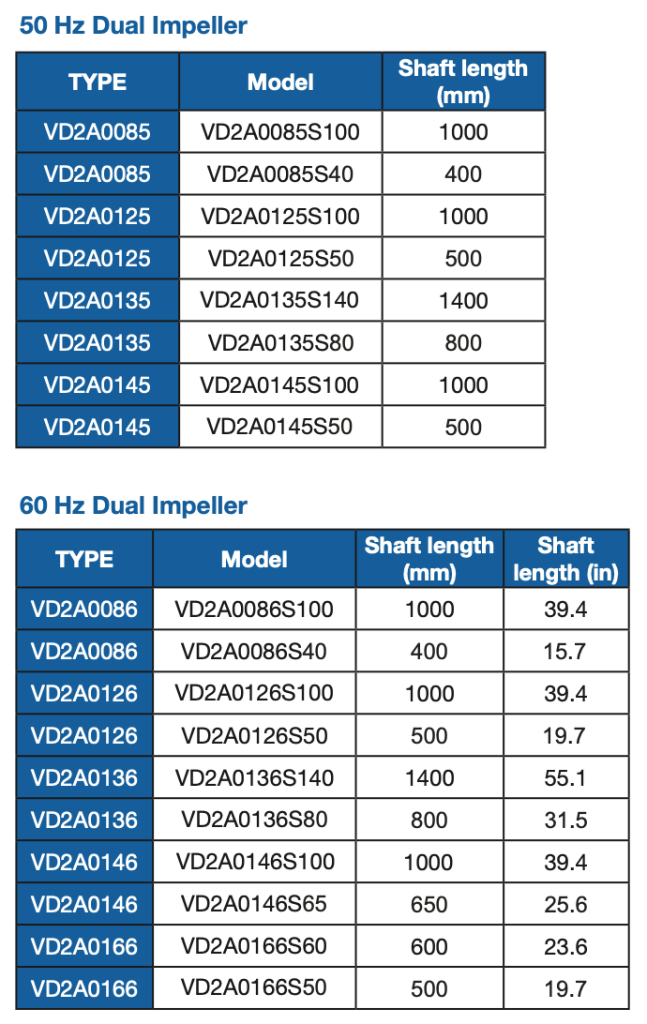

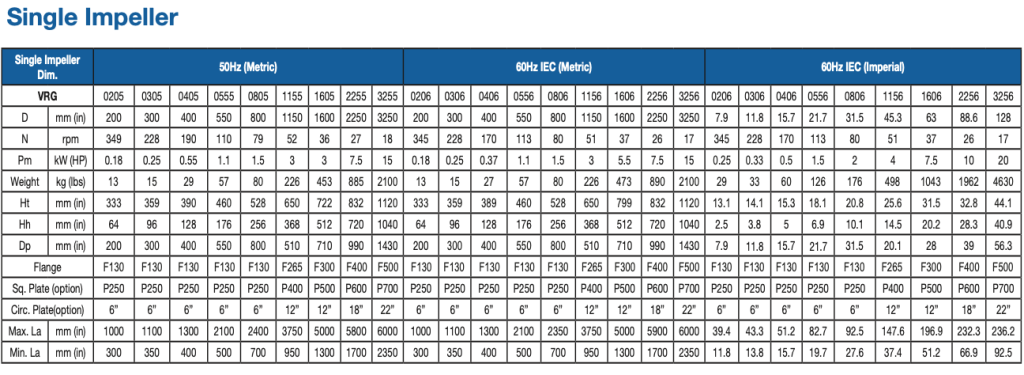

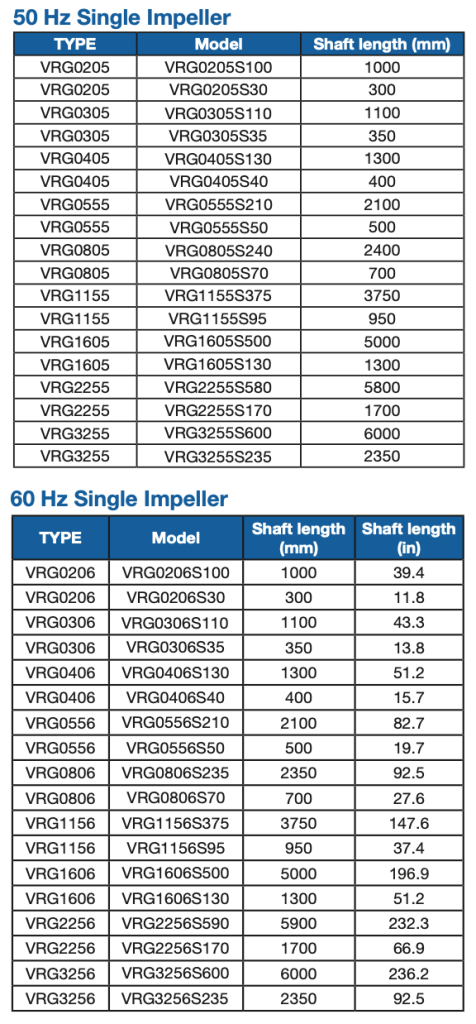

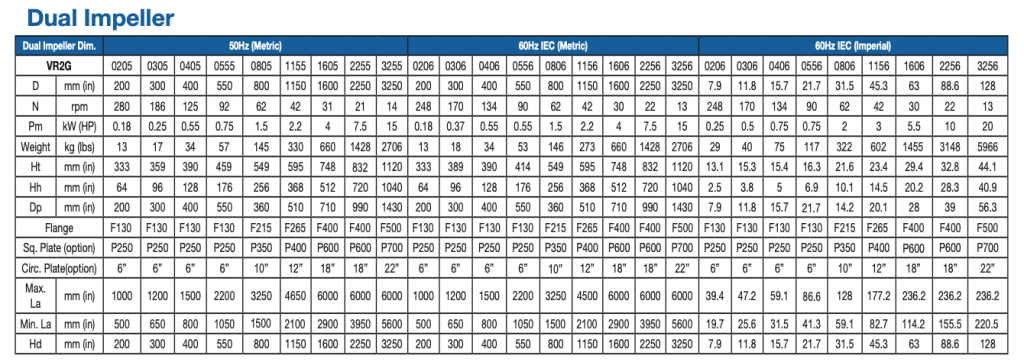

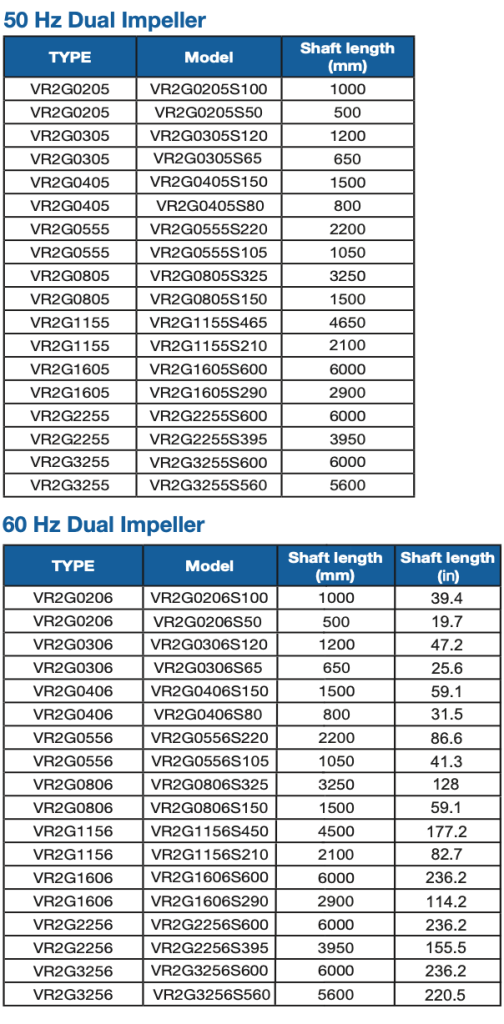

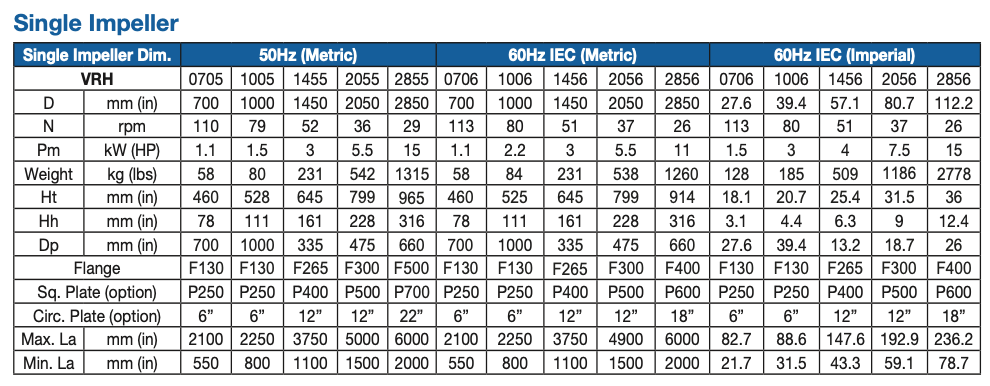

VRG Series

High Flow In a Lightweight Mixer with Uncompromising Results

With the VRG mounted with a SABRE propeller, to support a wide range of open or closed tank applications up to 10m (33ft) diameter (1800 m³ – 475000 gallons) and viscosities up to 1000 mPas (cP) at 1.3 specific gravity.

The VRG model is a gearmotor driven mixer equipped with the SABRE 10SG propeller with 3 blades. The SABRE propeller was specifically designed to deliver high and broad flow with minimal power consumption. This makes it ideal for large tanks or high mixing levels.

Powerful and compact, the VRG model provides high flow in a lightweight mixer with uncompromising results.

Gearmotor-driven mixer with robust performance

Equipped with high-efficiency 3-blade SABRE 10SG propeller

Delivers strong, broad flow with minimal power consumption

Compact design ideal for large tank applications

Easy to install and maintain

Operates during tank filling and emptying

Frequency inverter compatible for variable speed control

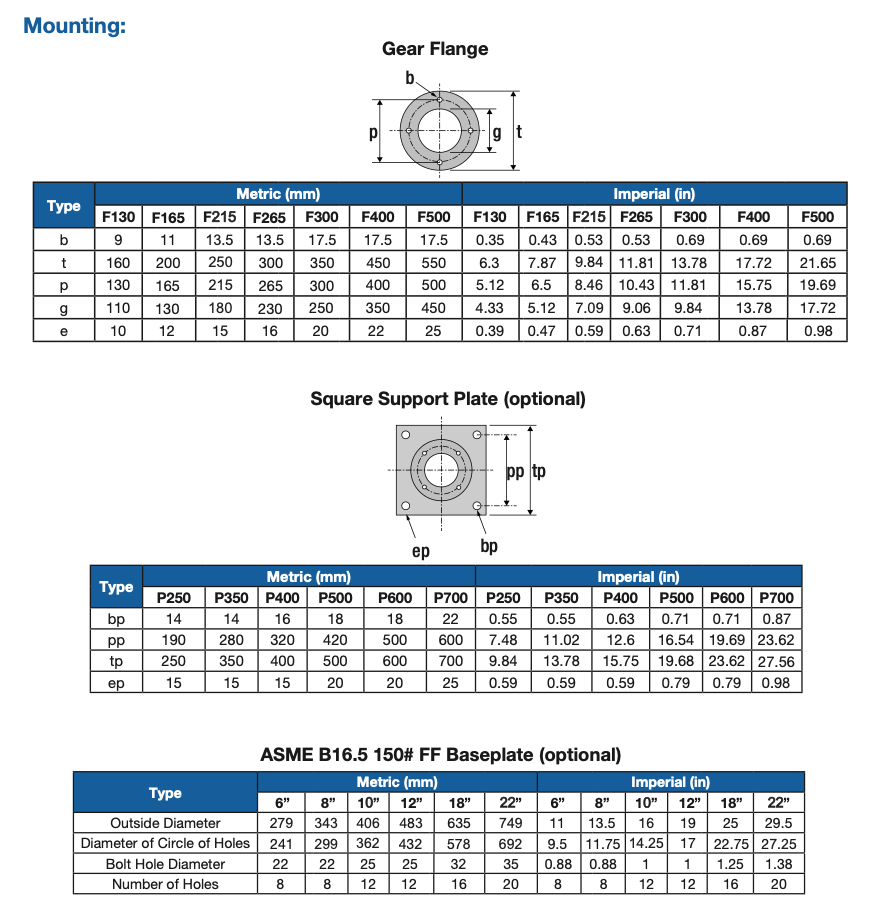

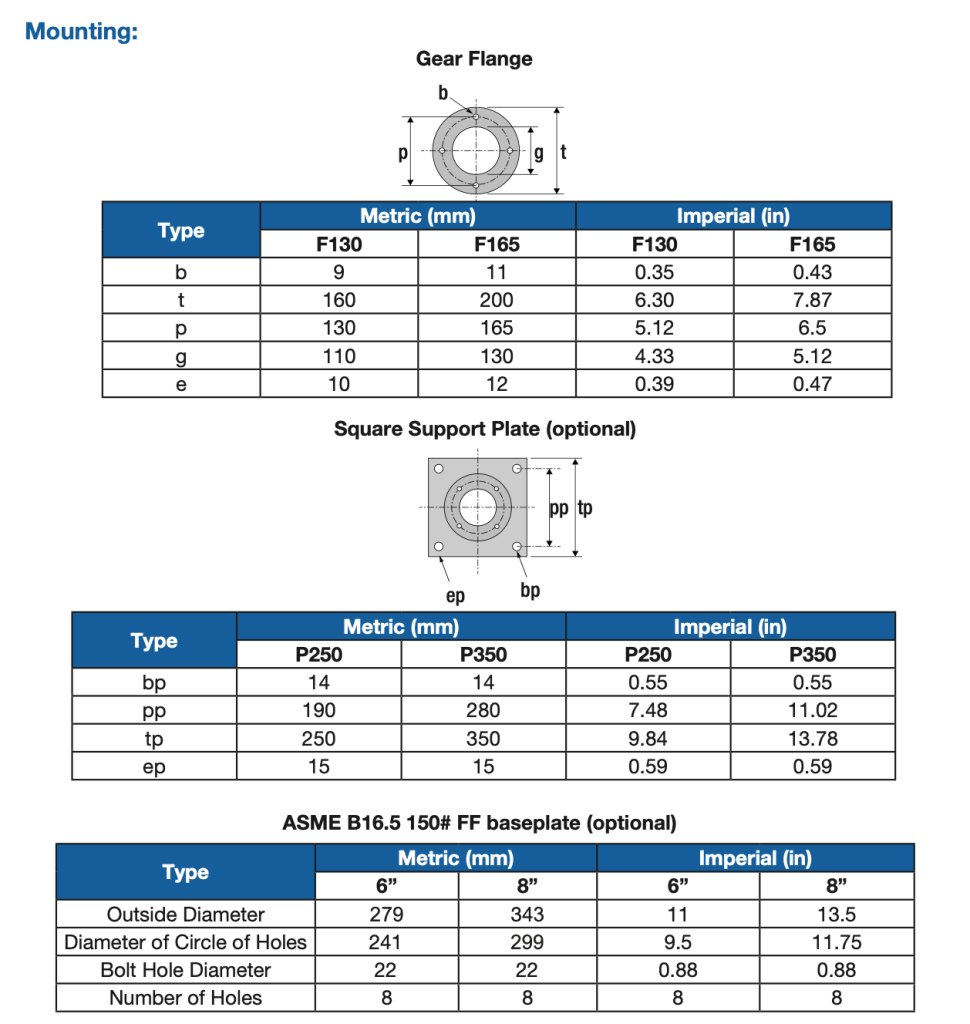

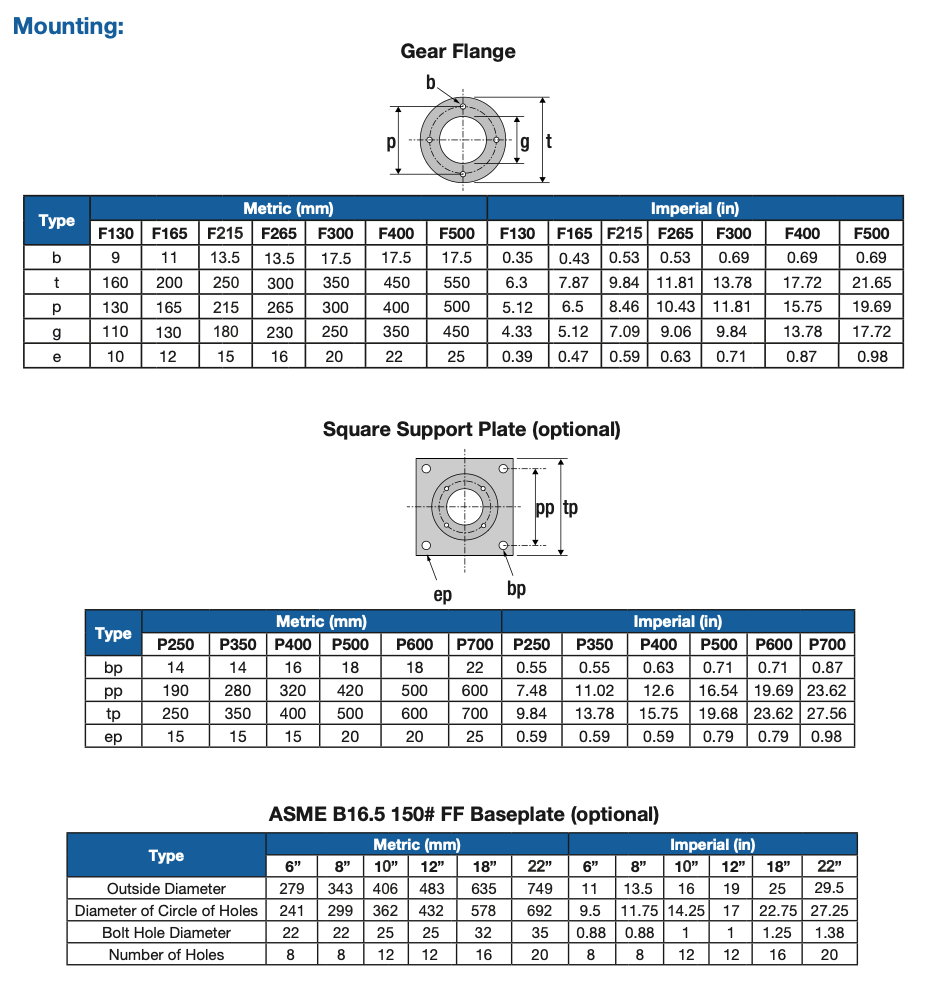

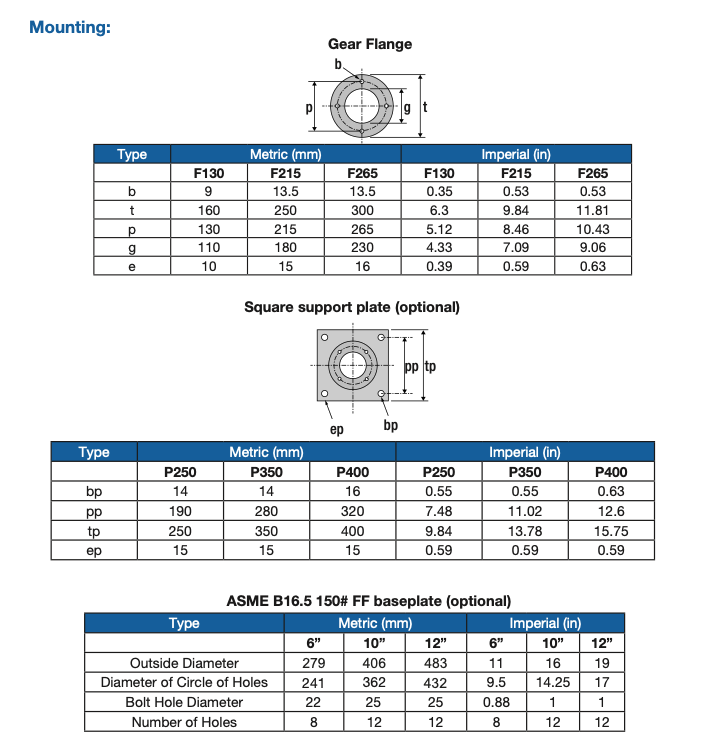

Multiple mounting options: direct, square, or ASME flange

Optional 1 or 2 impellers

Available with upward or downward flow configuration

Optional coated wetted parts (Abcite)

Stainless steel 316L wetted parts for corrosion resistance

Durable PU coating (RAL 1018) on drive system

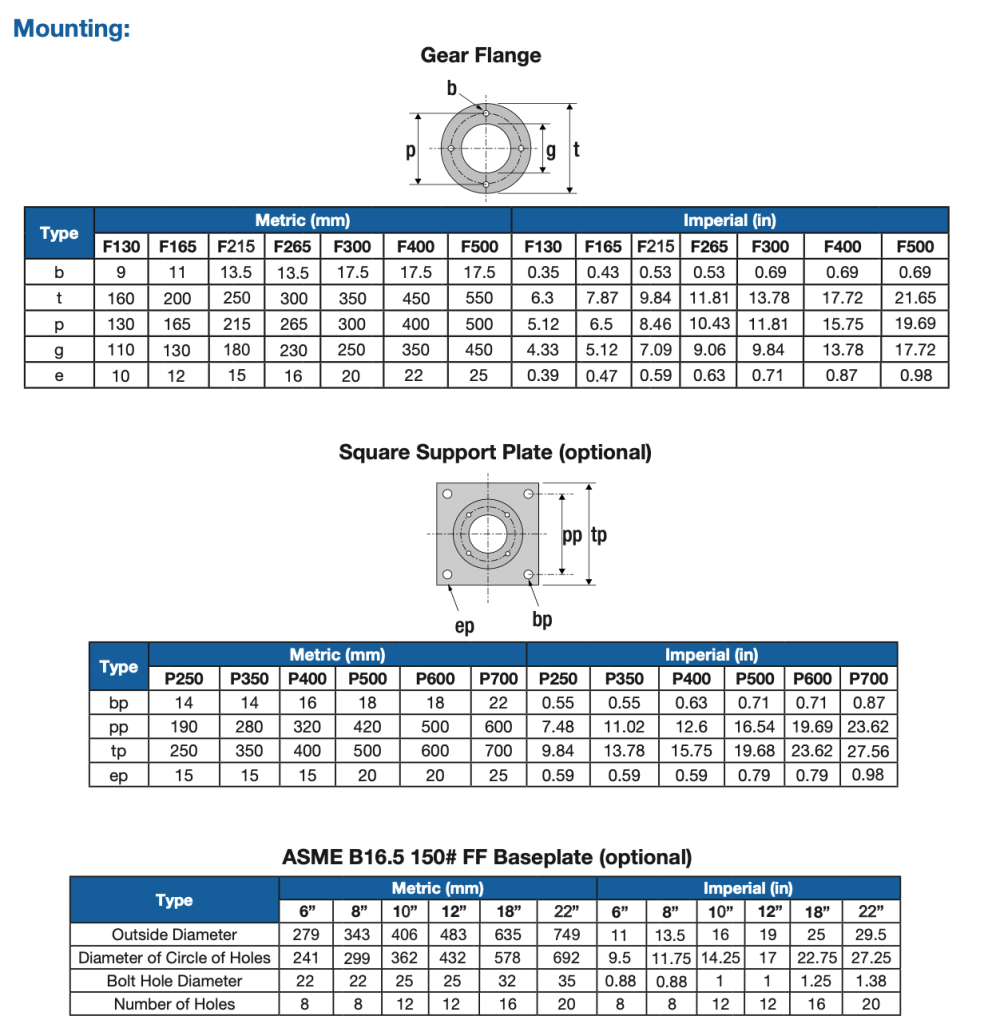

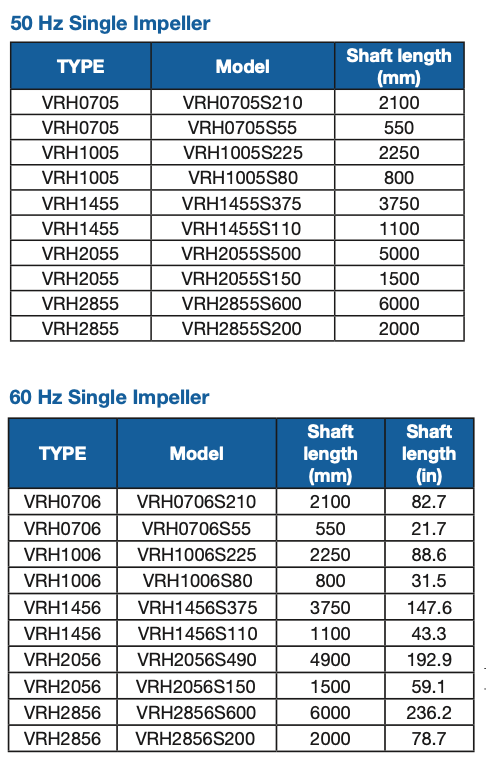

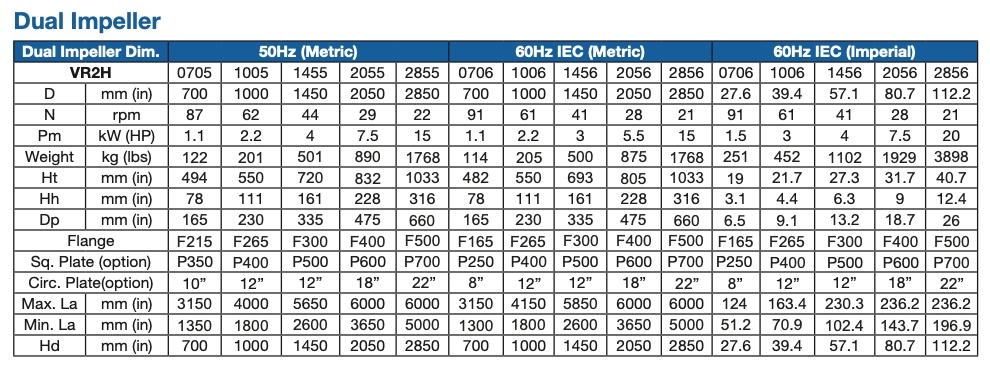

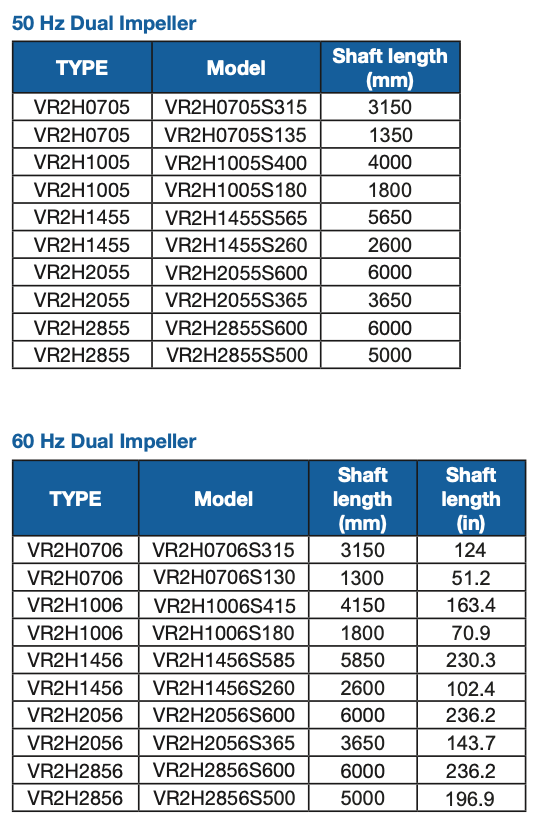

vrh Series

High-Performance Mixing

with the VRH Gearmotor Mixer

With the VRH mounted with a HXP propeller, to support a wide range of open or closed tank applications up to 9.5m (31ft) diameter (1200m³ – 317000 gallons) and viscosities up to 1,000 mPas (cP) at 1.3 specific gravity.

The VRH model is a gearmotor driven mixer equipped with the HXP-HP1 propeller with 3 blades. This is a powerful mixer with an improved hydraulic efficiency to meet the demands of a wide range of applications.

Powerful and compact, the VRH model provides energy efficiency in a lightweight mixer with uncompromising results.

-

Gearmotor-driven mixer with enhanced hydraulic efficiency

-

Equipped with HXP-HP1 hydrofoil impeller (3 blades)

-

Designed for tanks up to 9.5 m (31 ft) in diameter

-

Handles viscosities up to 1,000 mPas (cP) at 1.3 specific gravity

-

Rated power range: 1.1 to 15 kW (1.5 to 20 HP)

-

Easy to install, operate, and maintain

-

Operates during tank filling and emptying

-

Frequency inverter compatible for variable speed control

-

Available with upward or downward flow configuration

-

Supports 1 or 2 propeller options

-

Multiple mounting configurations: direct, square baseplate, or ASME flange

-

Wetted parts in stainless steel 316L

-

Durable PU coating (RAL 1018) on the drive system

-

Optional Abcite coating for added corrosion protection

-

Custom material options available on request

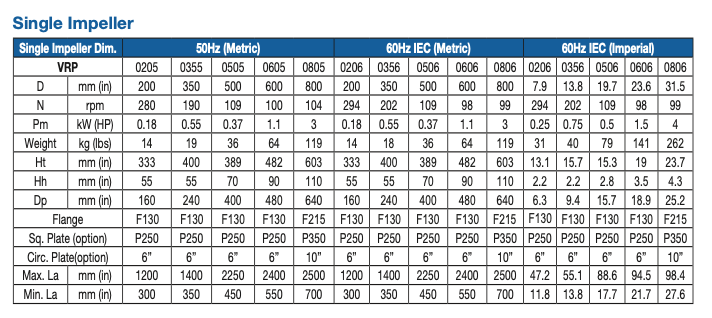

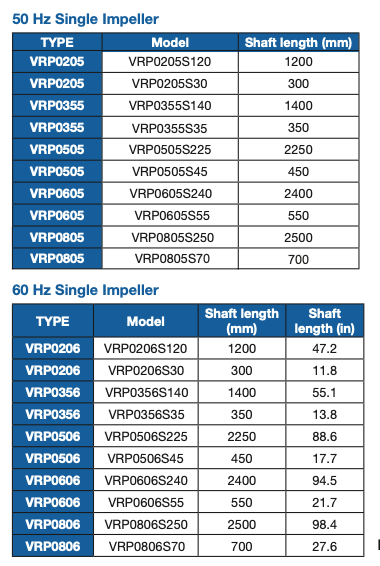

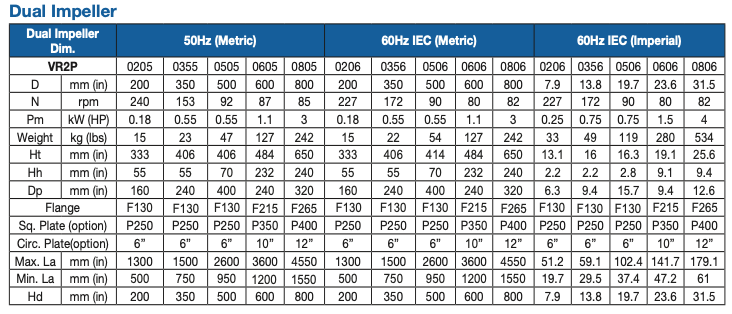

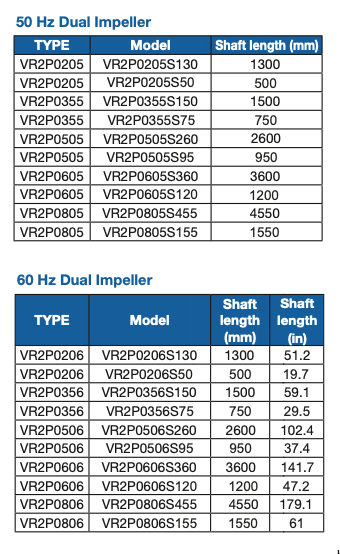

VRP SERIES

Efficient Mixing with the VRP PBT Mixer for Medium-Sized Tanks

With the VRP fitted with a PBT impeller, to support a wide range of open or closed tank applications up to 4m (13ft) diameter (90m³ – 23800 gallons) and viscosities up to 1,000 mPas (cP) at 1.3 specific gravity.

The VRP model is a gearmotor driven mixer using a pitch blade turbine (PBT) impeller. An ideal mixer for a wide range of applications, the VRP offers mixing during emptying, filling or with a variable speed drive.

Powerful and compact, the VRP model provides energy efficiency in a light-weight mixer with uncompromising results.

Gearmotor-driven mixer with reliable performance

Fitted with a 4-blade Pitch Blade Turbine (PBT) impeller

Designed for tank diameters up to 4 m (13 ft)

Handles viscosities up to 1,000 mPas (cP) at 1.3 specific gravity

Rated power range: 0.18 to 3 kW (¼ to 4 HP)

Suitable for blending, homogenization, dissolution, and reagent preparation

Operates during filling and emptying

Compatible with frequency inverters for variable speed control

Easy to install and maintain, reducing downtime

Multiple mounting options: direct, square baseplate, ASME flange

Wetted parts in stainless steel 316L

Durable PU-coated drive system (RAL 1018)

Optional 1 or 2 impellers

Available in upward or downward flow configurations

Optional Abcite coating for enhanced protection on solid shaft

Trusted by the best companies in Indonesian