High Performance HM Top Entry Mixers for Demanding Industrial Application

Built for water treatment, chemical processing, mining, and more. Milton Roy HM mixer delivers high flow, energy efficiency, and long-lasting performance. Designed for open tank applications, it's backed by CFD analysis for optimized, proven results in demanding environments.

Why Choose Us?

The HM Top-Entry Mixer is engineered to meet the toughest demands across water treatment, chemical processing, mining, and general industrial applications. It is designed for open tank systems of any volume, with a high-powered impeller that ensures superior flow and even velocity distribution throughout the tank. Supported by Milton Roy’s advanced Computational Fluid Dynamics (CFD) analysis, each mixer is precisely configured and scientifically verified to deliver optimal mixing results.

The HM mixer combines compact construction with powerful performance. It offers significant energy savings, operates reliably in harsh environments, and provides a long service life with minimal maintenance. When you need a solution that delivers performance, precision, and proven durability, Milton Roy is the name you can trust.

TOP ENTRY MIXERS

Powerful, Efficient Mixing

for Demanding Applications

The Milton Roy HM top-entry mixer is a configured unit engineered specifically for water treatment, chemical processing, mining, and general industry. Ideal for open tank applications in any volume, the mixer’s high powered impeller provides greater flow and better velocity distribution throughout the tank. Milton Roy’s Computational Fluid Dynamics (CFD) analysis ensures the ideal mixing results with scientific verification of your process.

The HM mixer is a compact yet powerful unit designed for robust environments, energy savings, and a long product life for years of reliable performance.

Modular configuration to meet specific application needs

Configured components in stock for fast build and ship, short lead-times

Easy mounting via adapter plate or standard ANSI mounting flanges to a square support on open tank applications

Multiple mixers can be installed on a single tank

100+ year history for added product confidence

Energy efficient for added savings

Reliable operation with consistent results

Easy to maintain, saving valuable time and resources

Designed for rotation during filling and emptying of tank for optimum performance

Operation

- Atmospheric pressure, outside location

- Temperature range <176°F (<80°C)

Mixer data

- Rated power: 0.37 to 37kW

- Rotation speed 5 to 300 rpm

- Shaft length up to 12m

Electrical data

- 230 to 690 Volts

- 50 Hz, 60Hz, low voltage, energy efficient

- IP 55, 65, 66, . . .

Materials

- Stainless steel 316L or 304, duplex, super-duplex

- Painting: According to C2-C3-C4-C5

- Motors based on country regulations and environment requirements

- Upgraded materials for aggressive environments

- Variety of impellers to choose from including the SABRE® impeller

- ATEX option

- Variable speed

ISO 9001

ISO 14001

OHSAS

GOST_R

ATEX / UL Compliance (optional)

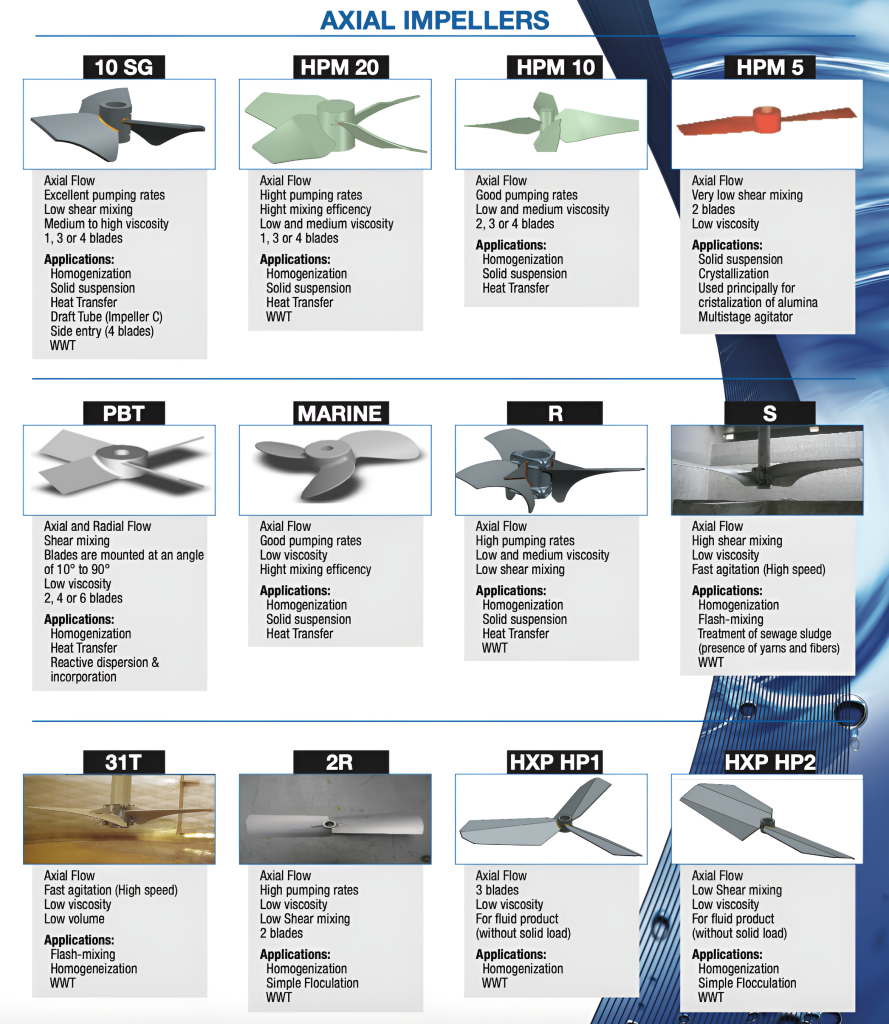

PBT – Axial or Radial Flow

HPM 20 – Axial Flow

HPM 10 – Axial Flow

10 SG – Axial Flow

R – Axial Flow

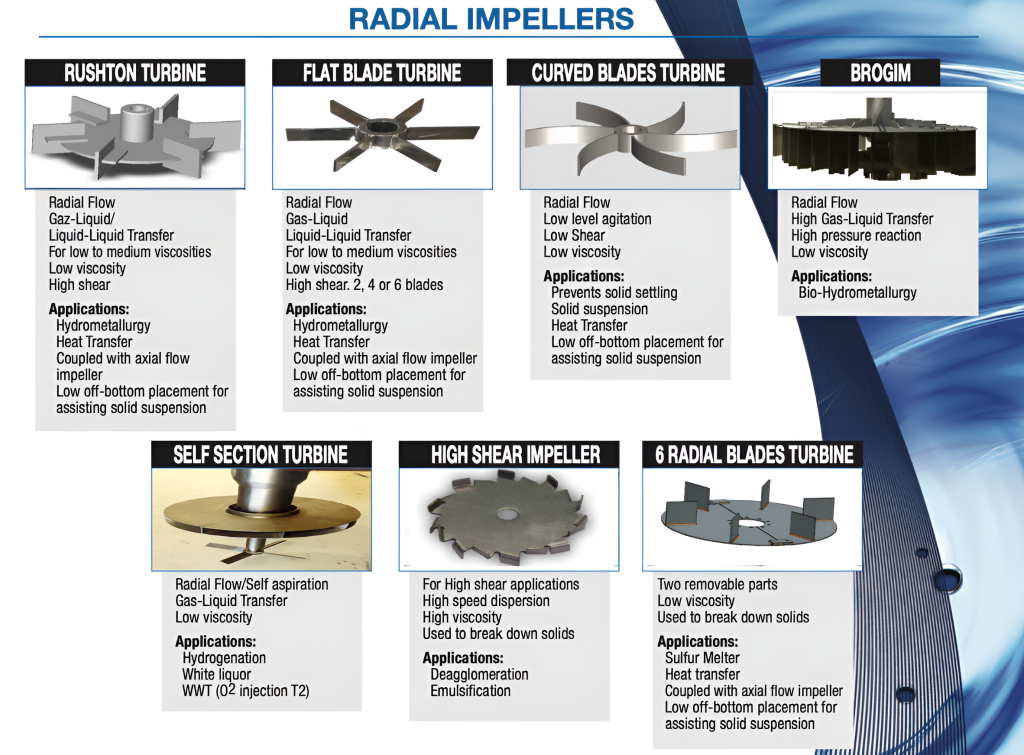

Rushton Turbine – Radial Flow

Curved Blade Turbine – Radial Flow

Flat Blade Turbine – Radial Flow

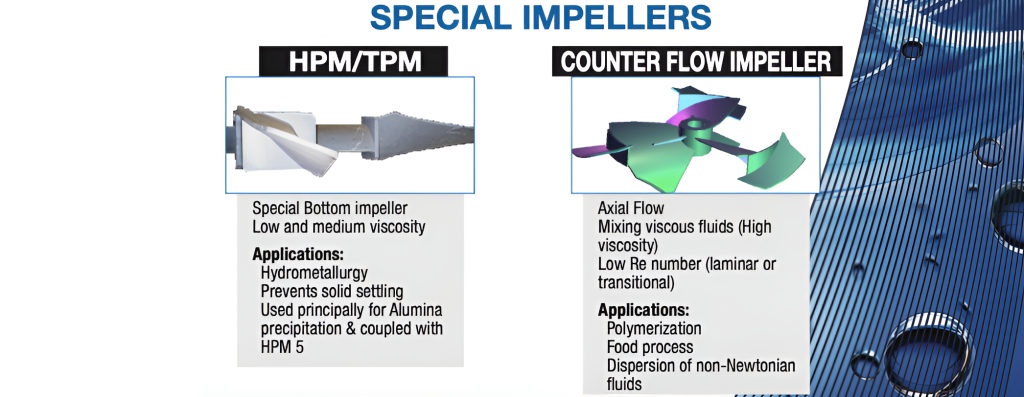

Counter Flow Impeller – Axial Flow

impellers type

Versatile Impeller Designs

for Every Mixing Challenge

Trusted by the best companies in Indonesian